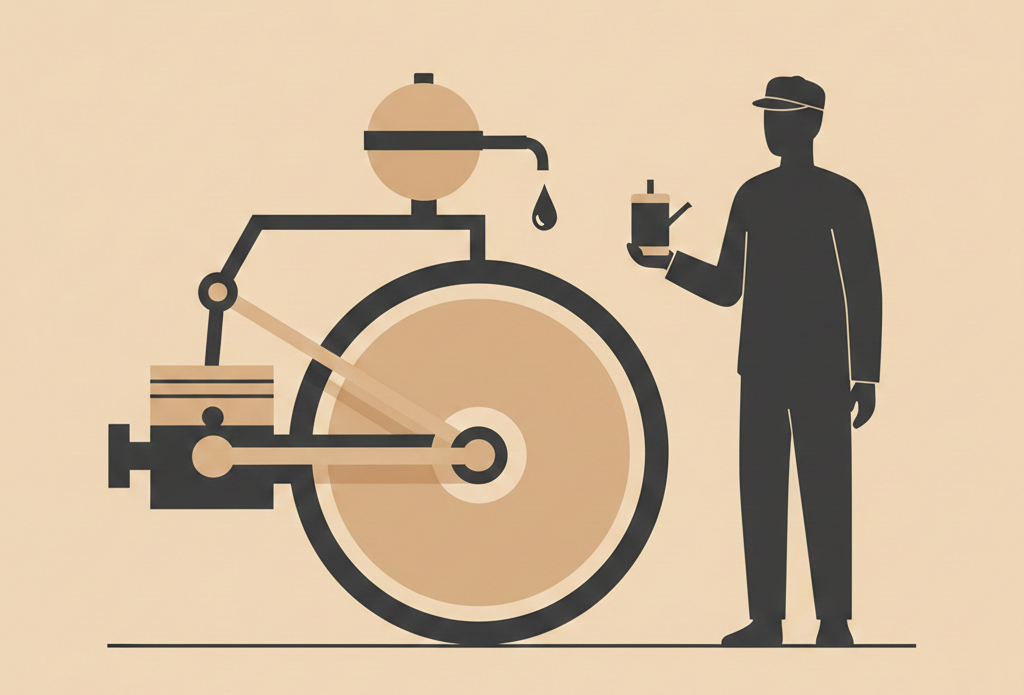

Elijah McCoy’s lubricating cup was a breakthrough that reshaped the industrial world. By feeding oil to the right joints while machines stayed in motion, he turned fragile steam engines into reliable systems that could move freight, people, and production without constant interruption. His quiet mechanism became so trusted that engineers insisted on getting the real McCoy, a phrase that carried his standard into everyday language.

The Lubricating Cup And The Logic Behind It

McCoy worked as a fireman and oiler on the Michigan Central Railroad, a job that placed him under the engine rather than behind a drafting table. Every stop to manually oil moving parts meant lost time, lost money, and increased risk. He saw the pattern. Machines did not fail from mystery. They failed at the joint where heat, friction, and pressure converged.

His solution was a small, disciplined mechanism that released oil continuously while the engine ran. It was not decorative. It was not theoretical. It was structural protection. This is why factories, locomotives, and marine engines began to run with fewer emergencies and fewer breakdowns. The lubricating cup introduced the idea that reliability could be built into the system instead of performed manually.

Bio Snapshot

Born in 1844 in Colchester, Ontario, to parents who had escaped enslavement through the Underground Railroad, Elijah McCoy grew up in a community built on discipline and survival. He trained as a mechanical engineer in Scotland before returning to North America. Racial barriers limited his opportunities, but he used the railroad job he was given to study failure patterns up close. His first major patent was awarded in 1872, and he went on to develop dozens of lubrication systems that improved safety and efficiency across multiple industries.

The Life Of Elijah McCoy: What We Know

McCoy spent years refining his initial lubrication design, adapting it to different engine layouts and industrial settings. Some devices released oil through gravity, others through steam pressure or mechanical valves. Each version was a response to the same question: how do you keep motion smooth without stopping the machine. His later years included consulting work and continued invention, leaving a record of innovation tied directly to the safety and efficiency of modern industry.

The Modern Echo Of McCoy’s Lubricating Cup

The logic of McCoy’s design travels through heavy industry, manufacturing, logistics, and modern engineering. Automated lubrication is now embedded in factory bearings, automotive engines, aerospace components, and industrial plants. The principle is the same. Protect the point of friction. Reduce the heat. Extend the life of the system.

His cultural echo is just as significant. When buyers asked for the real McCoy, they were requesting reliability, not trend. They wanted the design that held up under pressure. A Black engineer’s name became shorthand for authenticity in a world overflowing with cheap shortcuts. The phrase lives on because the standard remains true.

The Architecture Of Reliability

McCoy’s work reminds us that reliability is not luck. It is the result of disciplined structure. His cup automated a task that everyone assumed would always be manual, messy, and inefficient. By designing the mechanism instead of accepting the problem, he shifted entire industries from interruption to flow.

This is the heart of structural thinking. Do not force people to do what a system should handle. Build the protection into the infrastructure so the whole machine runs with less strain and fewer emergencies.

The Groundwork For Us

Groundwork Daily reads Elijah McCoy as a case study in how small, disciplined mechanisms create large, lasting shifts. He solved a hidden problem that most people had accepted as a permanent burden. He designed a simple structure that protected the entire operation. His legacy is less about the device and more about the mindset.

Our mandate is to honor the origin, document the builder, and build systems where future innovators are not forgotten or footnoted. When reliability becomes culture, everything moves with more dignity and less chaos.

Takeaway: Reliability is architecture. When you design a mechanism that reduces friction, you change the pace and stability of everything connected to it.

- Receipts

- United States Patent (1872) automatic lubricator for steam engines

- Smithsonian National Museum of American History documentation on lubrication systems

- Library of Congress technical records on early industrial maintenance devices